LightSpray Manufacturing Technique Revolutionizes Running Shoes

The LightSpray manufacturing technique is revolutionizing the world of running shoes innovation, offering a glimpse into the future of automated shoe production. Developed by the Swiss sneaker company On, this innovative process significantly reduces the need for manual labor, traditionally involving around 200 workers. Instead, a high-tech robot employs a spray gun to coat a rotating mold with a synthetic polymer, efficiently crafting the upper of the sneakers in just minutes. The result is a seamless, lace-free design that fits like a sock, underscoring the advancements in sneaker upper manufacturing. As On prepares to scale production from a few thousand to millions, the LightSpray technique positions the company at the forefront of Swiss sneaker technology.

Introducing the LightSpray method, a groundbreaking approach that redefines sneaker production in the footwear industry. This technique employs automated systems to streamline the creation of shoe uppers, enhancing both efficiency and design quality. By utilizing a specialized spray gun, brands like On are able to achieve a snug fit and seamless construction that could change consumer expectations for athletic footwear. As demand for innovative solutions in shoe manufacturing grows, the LightSpray process stands out as a pivotal development in the evolution of sneaker craftsmanship. This advancement not only highlights the integration of technology in sports apparel but also sets new standards for how running shoes are conceived and produced.

The Innovative LightSpray Manufacturing Technique

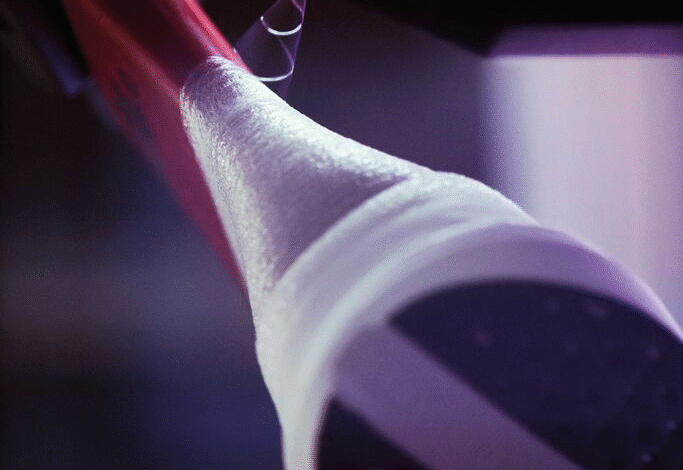

The LightSpray manufacturing technique is revolutionizing the way running shoes are produced, merging technology with efficiency. Developed by the Swiss sneaker company On, this groundbreaking production method utilizes automated machines to spray a synthetic polymer onto molds shaped like a foot. This results in a seamless shoe upper that enhances comfort and performance. Unlike traditional manufacturing, which requires a labor-intensive process involving numerous workers, LightSpray can streamline production, significantly cutting down on labor costs while maintaining high-quality standards.

Marc Maurer, On’s former co-CEO, highlighted the efficiency of the LightSpray technology, noting that it reduces the number of personnel required for production from approximately 200 to just a few automated systems. This innovative approach not only minimizes human error but also allows for a rapid production cycle. Each shoe upper is created in roughly three minutes, ensuring that the company can keep up with high demand without compromising on quality.

Frequently Asked Questions

What is the LightSpray manufacturing technique in running shoe production?

The LightSpray manufacturing technique is an innovative method developed by the Swiss sneaker company On, allowing for the automated production of sneaker uppers using a spray gun. This process involves spraying a synthetic polymer material onto a rotating mold, creating a seamless and lightweight shoe upper that fits snugly like a sock.

How does LightSpray improve the efficiency of automated shoe production?

LightSpray significantly enhances the efficiency of automated shoe production by reducing the workforce needed for traditional manufacturing methods. While conventional sneaker upper manufacturing may require around 200 people, LightSpray can produce a shoe upper in just three minutes with the help of advanced robotic systems, greatly increasing production capacity.

What advantages does LightSpray offer in running shoes innovation?

LightSpray offers several advantages in running shoe innovation, including reduced production time, seamless construction for enhanced comfort, and the ability to scale production from thousands to millions of pairs. This method also minimizes waste and enhances the precision of sneaker design, positioning On as a leader in the industry.

How does the LightSpray technique utilize Swiss sneaker technology?

The LightSpray technique exemplifies Swiss sneaker technology by integrating precision engineering and advanced robotics into the manufacturing process. This method reflects Switzerland’s reputation for innovation in high-quality production and pushes the boundaries of conventional techniques in sneaker upper manufacturing.

What is the significance of On’s new LightSpray factory in Zurich?

The opening of On’s first LightSpray factory in Zurich marks a significant milestone in automated shoe production. This facility will feature four advanced robots dedicated to producing sneaker uppers using the LightSpray technique, enabling On to meet growing demand and enhance its competitive advantage in the running shoe market.

What type of material is used in the LightSpray sneaker upper manufacturing process?

In the LightSpray sneaker upper manufacturing process, a synthetic polymer material is used. This polymer is sprayed onto a mold to create a flexible and durable upper that conforms to the shape of the foot, offering both comfort and performance for runners.

Can you explain how the LightSpray manufacturing technique benefits athletes?

The LightSpray manufacturing technique benefits athletes by producing lightweight and highly breathable shoe uppers that fit securely and comfortably. This design reduces the chances of blisters and discomfort during runs, enhancing overall performance and experience for athletes.

What are the future implications of the LightSpray technique for the sneaker industry?

The LightSpray technique has vast future implications for the sneaker industry, including potential shifts toward more sustainable manufacturing practices and the ability to rapidly adapt designs based on consumer preferences. This advances the evolution of sneaker production, pushing traditional boundaries and setting new standards for efficiency and innovation.

| Key Point | Details |

|---|---|

| Manufacturing Technique | LightSpray allows for the automated production of running shoe uppers using spray technology. |

| Efficiency | The process is completed by robots, reducing labor from 200 workers to a few automated machines, enhancing efficiency. |

| Production Time | Each shoe upper can be produced in approximately three minutes. |

| Product Design | The shoes are seamless, lace-free, and designed to fit snugly like a sock. |

| Future Plans | On aims to scale production from thousands to millions of pairs. |

| New Factory | The first LightSpray factory opened in Zurich with four advanced robots for production. |

| Competitive Advantage | Innovations like LightSpray give On a competitive edge in the sneaker market. |

Summary

The LightSpray manufacturing technique revolutionizes the way running shoes are produced, emphasizing automation and efficiency. By using a spray gun, On can create shoe uppers seamlessly and in record time, contrasting sharply with traditional methods that require extensive manual labor. This cutting-edge approach positions On to not only enhance production efficiency but also to meet increasing market demands effectively.